As eCommerce continues to evolve, brands are under increasing pressure to ship faster, manage more SKUs, and control fulfillment costs — all without overcommitting to warehouse space. Traditional pallet-based warehousing often fails to meet these needs, especially for modern eCommerce businesses with diverse product catalogs and fluctuating inventory levels.

This is where merchant bin store fulfillment comes in.

Bin-based fulfillment is a flexible, efficient warehousing model built specifically for today’s eCommerce operations. Instead of storing products on full pallets, inventory is organized into individual bins, allowing for faster picking, better space utilization, and lower costs for growing brands.

In this article, we’ll break down what merchant bin store fulfillment is, how it works, and why eCommerce brands should seriously consider it as they scale.

What Is Merchant Bin Store Fulfillment?

Merchant bin store fulfillment is a warehouse storage and order fulfillment method where individual SKUs are stored in labeled bins rather than on pallets or large shelving units designed for bulk inventory.

Each bin typically contains a single SKU or product variation and is strategically placed within a picking system that prioritizes speed and accuracy. Warehouse staff can quickly locate items, pick orders efficiently, and move them directly to packing stations.

This model is especially effective for:

-

Brands with many SKUs

-

Products with small to medium unit sizes

-

Businesses that sell direct-to-consumer (DTC)

-

Companies experiencing frequent inventory changes

Unlike pallet storage, bin fulfillment doesn’t require brands to maintain high inventory volumes to justify the space they’re paying for.

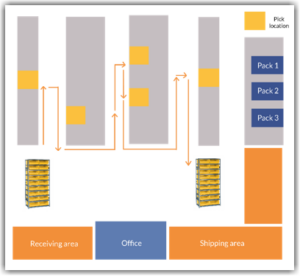

How Bin Store Fulfillment Works

The bin fulfillment process is designed around efficiency and visibility. Here’s how it typically works:

-

Inbound Receiving

Inventory arrives at the warehouse and is checked in by SKU, quantity, and condition. -

Bin Assignment

Products are placed into assigned bins based on size, velocity, and picking frequency. -

Inventory Tracking

Each bin is tracked through a warehouse management system (WMS), providing real-time inventory visibility. -

Order Picking

When an order is placed, pickers retrieve items directly from bins using optimized pick paths. -

Packing & Shipping

Orders move immediately to packing stations and are prepared for outbound shipping.

This streamlined process reduces unnecessary movement, shortens pick times, and minimizes fulfillment errors.

Why Pallet Storage Doesn’t Work for Most eCommerce Brands

Traditional pallet-based warehousing was built for bulk distribution — not modern eCommerce.

Many growing brands struggle with pallet storage because:

-

They don’t consistently fill full pallets

-

Inventory levels fluctuate seasonally

-

SKUs change frequently

-

They pay for unused space

For eCommerce brands shipping individual orders, pallet storage often creates wasted space, slower picking times, and higher costs. Bin fulfillment, by contrast, is designed around unit-level picking, which aligns perfectly with DTC and omnichannel sales models.

Key Benefits of Merchant Bin Store Fulfillment

1. Faster Order Fulfillment

Bins allow pickers to locate products quickly without navigating pallet racks or forklifts. This results in shorter pick times and faster order processing — a major advantage for brands promising 2-day or next-day delivery.

2. Lower Storage Costs

Brands only pay for the space their inventory actually occupies. There’s no need to reserve full pallets for partially filled inventory, making bin fulfillment more cost-effective.

3. Improved Order Accuracy

Bin systems reduce picking errors by clearly separating SKUs and minimizing confusion during fulfillment. This leads to fewer returns, exchanges, and customer complaints.

4. Easy SKU Expansion

Launching new products or variants is simple — just assign a new bin. There’s no need to reconfigure pallet layouts or renegotiate storage minimums.

5. Better Inventory Visibility

With bins tied directly to a WMS, brands gain real-time insight into stock levels, product movement, and reorder points.

Who Benefits Most from Bin Store Fulfillment?

Merchant bin store fulfillment is especially well-suited for:

-

Apparel and fashion brands

-

Beauty and cosmetics companies

-

Health and wellness products

-

Subscription box businesses

-

Consumer packaged goods (CPG) brands

-

Startups and fast-growing eCommerce sellers

If your brand ships individual units rather than bulk pallets, bin fulfillment is likely a better operational fit.

Bin Fulfillment vs Pallet Storage: A Quick Comparison

| Feature | Bin Store Fulfillment | Pallet Storage |

|---|---|---|

| Ideal for eCommerce | ✅ Yes | ❌ No |

| SKU flexibility | High | Low |

| Storage efficiency | Excellent | Inefficient for small volumes |

| Picking speed | Fast | Slower |

| Cost predictability | Usage-based | Fixed minimums |

Why Bin Fulfillment Scales Better as You Grow

As eCommerce brands grow, fulfillment complexity increases. More SKUs, higher order volumes, and new sales channels can quickly overwhelm rigid storage systems.

Bin fulfillment scales naturally with growth:

-

Add bins as inventory increases

-

Adjust picking zones based on order velocity

-

Expand without long-term storage commitments

This flexibility allows brands to grow without being locked into inefficient warehouse contracts or excessive overhead.

Why eCommerce Brands Should Care Right Now

Consumer expectations are rising, shipping windows are shrinking, and competition is fierce. Brands that rely on outdated fulfillment models risk falling behind on both cost and customer experience.

Merchant bin store fulfillment gives eCommerce brands:

-

Speed without overpaying

-

Flexibility without chaos

-

Accuracy without complexity

For companies focused on sustainable growth, bin fulfillment isn’t just a storage method — it’s a competitive advantage.

Final Thoughts

Merchant bin store fulfillment represents a smarter approach to modern eCommerce logistics. By prioritizing flexibility, efficiency, and cost control, bin-based warehousing aligns perfectly with how today’s brands sell and ship products.

If your business is growing, launching new SKUs, or struggling with pallet minimums, it may be time to rethink how your inventory is stored and fulfilled.